The Function of Mycotoxin testing Services in Food and Feed Security

The Function of Mycotoxin testing Services in Food and Feed Security

Blog Article

How Mycotoxin Testing Aids Prevent Contamination and Secure Food Materials

Mycotoxin testing is an essential practice in the food market, serving as a frontline protection versus contamination by unsafe toxins generated by mold and mildews. Through the application of advanced strategies like High-Performance Liquid Chromatography (HPLC) and Fluid Chromatography-Mass Spectrometry (LC-MS), food producers can precisely evaluate and identify mycotoxin degrees in farming products.

Understanding Mycotoxins

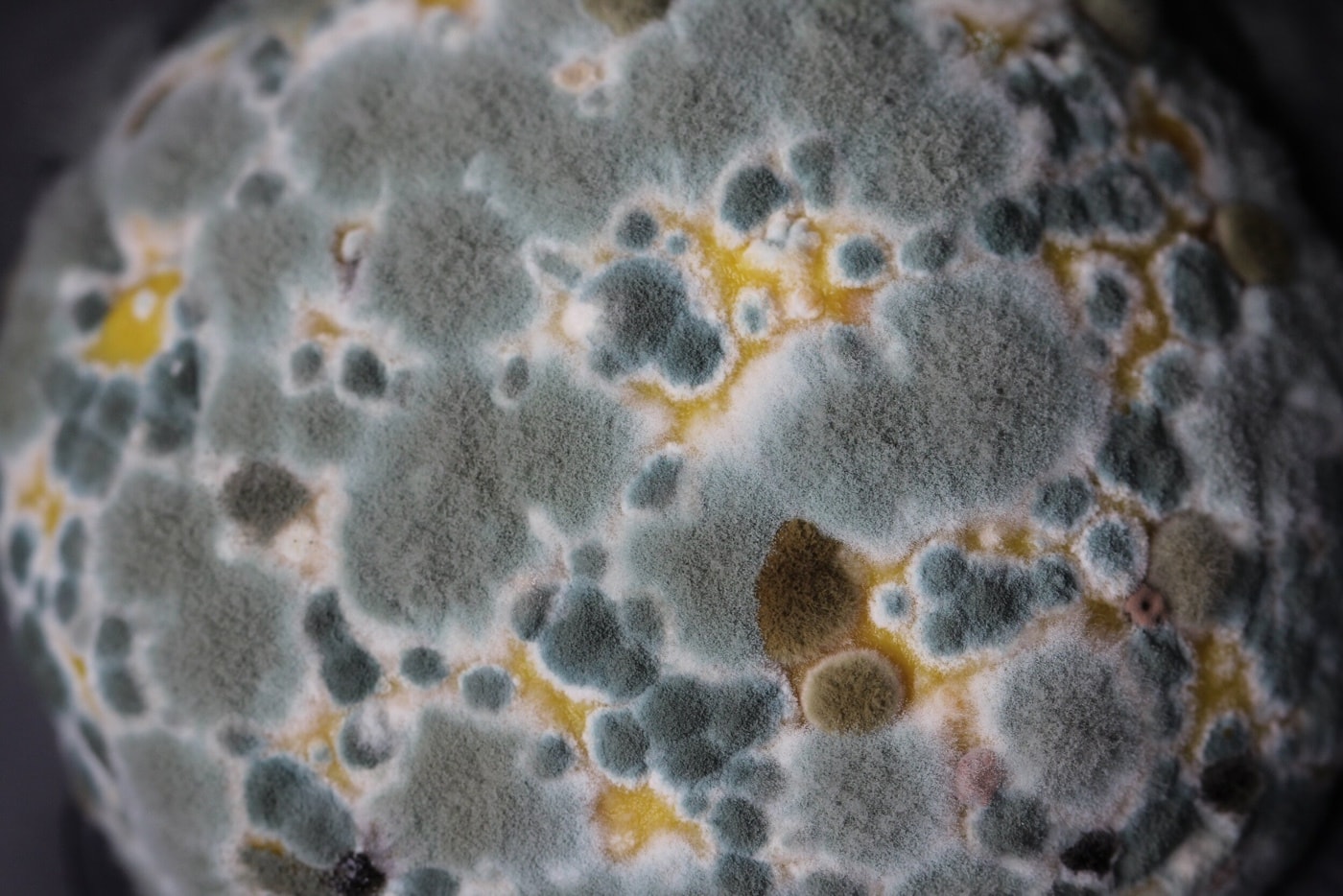

Recognizing mycotoxins begins with recognizing that they are poisonous secondary metabolites generated by particular mold and mildews, which can infect agricultural products. These metabolites are not important for the growth or reproduction of the fungis but can have serious ramifications for animal and human health. Mycotoxins are typically found in staple plants such as corn, wheat, barley, and nuts, where they can proliferate under certain conditions of wetness and temperature.

There are numerous types of mycotoxins, each generated by different fungal varieties. Fusarium varieties generate fumonisins and trichothecenes, both of which are associated with numerous severe and persistent health and wellness concerns.

Risks of Mycotoxin Contamination

The threats of mycotoxin contamination are diverse, posing considerable threats to both food security and public health and wellness. Mycotoxins, hazardous substances produced by certain types of fungis, can contaminate a wide array of agricultural items including cereals, nuts, seasonings, dried fruits, and coffee.

Economic effects are another major problem. Contaminated plants can cause considerable economic losses for farmers and food manufacturers because of lowered yields and the requirement for pricey purification steps. International trade can be substantially prevented as nations enforce strict mycotoxin policies to secure their populaces, leading to denied deliveries and strained trade relations.

Environmental elements such as climate modification worsen the danger of mycotoxin contamination. Variants in temperature level and moisture can produce desirable problems for fungal development, raising the chance of contamination occasions. Hence, understanding and minimizing these threats are critical for ensuring the safety and integrity of international food products.

Approaches of Mycotoxin Checking

Precisely determining mycotoxin contamination in agricultural products is important for safeguarding public health and keeping food safety and security criteria. Different methods are employed to detect and evaluate mycotoxins, each offering details benefits and limitations.

High-Performance Fluid Chromatography (HPLC) is a commonly made use of method as a result of its high level of sensitivity and precision. It involves dividing mycotoxins from other substances in an example, allowing accurate metrology. Fluid Chromatography-Mass Spectrometry (LC-MS) integrates fluid chromatography with mass spectrometry to supply comprehensive molecular details, making it especially valuable for determining multiple mycotoxins concurrently.

Gas Chromatography-Mass Spectrometry (GC-MS) and Thin-Layer Chromatography (TENDER LOVING CARE) are likewise utilized, each with distinct applications. GC-MS works for volatile mycotoxins, while TLC supplies a less complex, cost-efficient option for preliminary screening.

Advantages of Normal Checking

Routine testing for mycotoxins in farming items provides numerous advantages, dramatically adding to public wellness and food safety and security. By determining contamination early, regular screening assists avoid the distribution of poisonous foods, consequently decreasing the threat of mycotoxin-related ailments among customers. This positive method not just safeguards human health and wellness but additionally improves the total high quality of food supplies.

Regular testing additionally supports governing compliance. Various nations and regions have actually established stringent restrictions for mycotoxin degrees in food and feed. Complying with address these limitations through normal testing makes sure that providers and manufacturers meet lawful standards, consequently avoiding charges and profession barriers. Additionally, maintaining compliance cultivates consumer depend on and brand name track record, which are critical for market success.

Additionally, regular mycotoxin testing can result in considerable financial advantages. Early discovery of contamination permits prompt treatment, reducing potential losses from extensive contamination. Executing routine screening procedures can likewise lessen recall prices and relevant responsibilities, which can be monetarily ruining.

In addition, normal screening gives beneficial information that can educate far better farming methods and storage space conditions. By understanding patterns of contamination, manufacturers can adopt safety nets, thereby reducing future risks and adding to the sustainability of the food supply chain.

Implementing Evaluating Protocols

Implementing reliable mycotoxin screening protocols is important for making certain the security and top quality of agricultural products. Establishing a durable screening framework involves numerous crucial steps, beginning with the recognition of prospective contamination points within the manufacturing and supply chain. This includes pre-harvest, post-harvest, storage space, and circulation phases. Each stage needs to be scrutinized to determine where mycotoxin contamination is more than likely to happen.

As soon as important control points are determined, selecting proper testing techniques is important. Usual techniques consist of enzyme-linked immunosorbent assay (ELISA), high-performance liquid chromatography (HPLC), and mass spectrometry (MS) Each technique has its weak points and staminas; hence, choosing the right one depends on the certain mycotoxin being examined, the needed level of sensitivity, and available resources.

Last but not least, incorporating the testing methods into a thorough food security management system is suggested. This improves traceability and makes it possible for quick corrective activities when contamination is detected, consequently protecting the Clicking Here honesty of the food supply chain.

Final Thought

Mycotoxin screening is vital in avoiding contamination and securing food supplies by making it possible for early detection of harmful toxic substances generated by molds in farming items. Advanced methods such as HPLC and LC-MS make sure compliance with security laws and protect customers from wellness risks. Routine screening boosts brand track record, economic stability, and count on in food safety and security by minimizing contamination-related losses and maintaining high criteria in food production. Executing extensive screening methods is thus necessary for the sector's overall wellness.

Mycotoxin screening is an indispensable practice in the straight from the source food market, offering as a frontline protection versus contamination by harmful toxins produced by molds. An integrated technique including agricultural methods, storage space administration, and routine testing can reduce the risks connected with mycotoxin contamination, making certain food security and public health and wellness.

The risks of mycotoxin contamination are multifaceted, posturing considerable dangers to both food security and public health and wellness.Regular screening for mycotoxins in farming products supplies countless advantages, dramatically contributing to public health and food safety and security.Mycotoxin screening is vital in avoiding contamination and safeguarding food products by allowing early discovery of hazardous contaminants created by molds in farming products.

Report this page